Design and Drawing Documentation

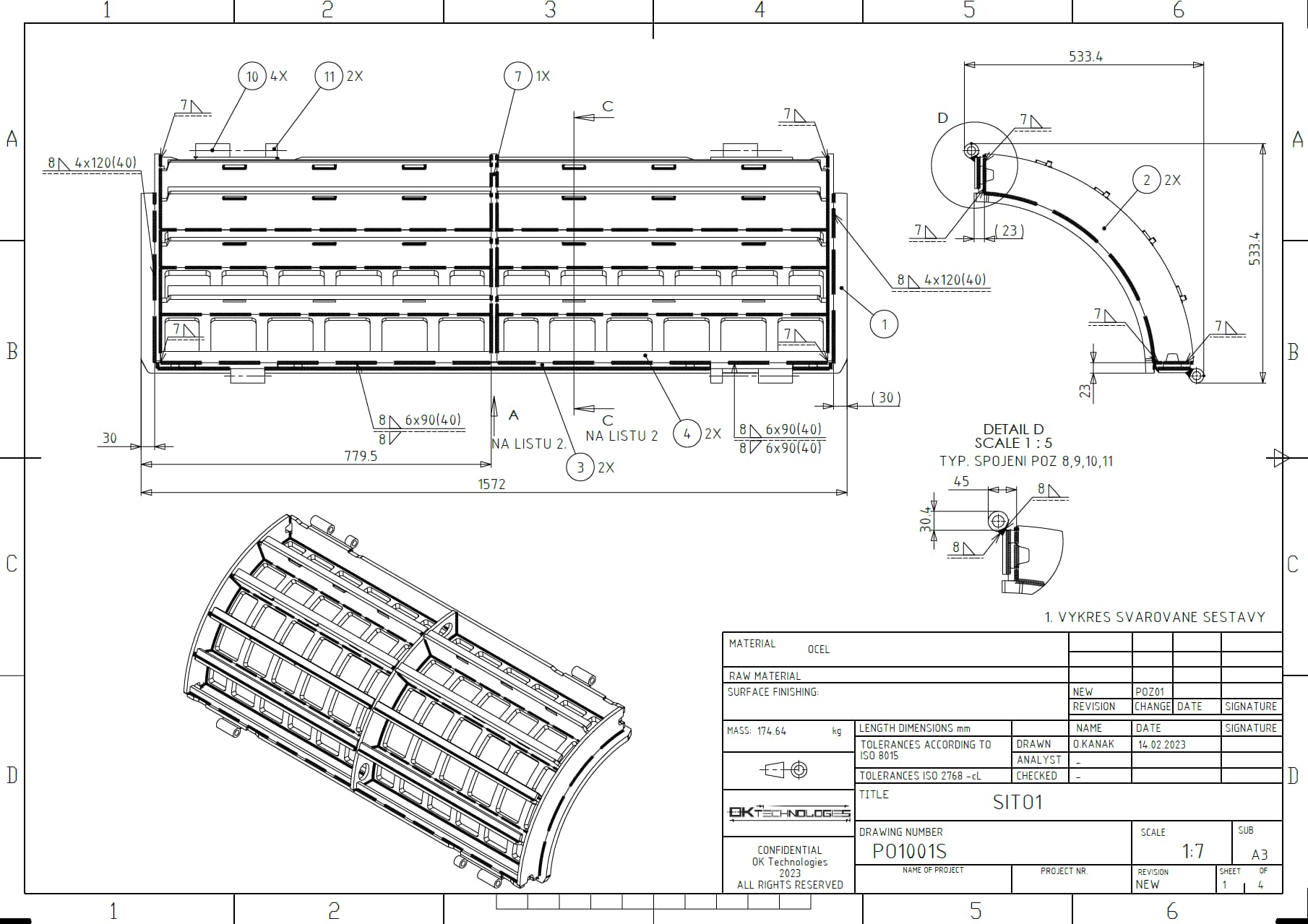

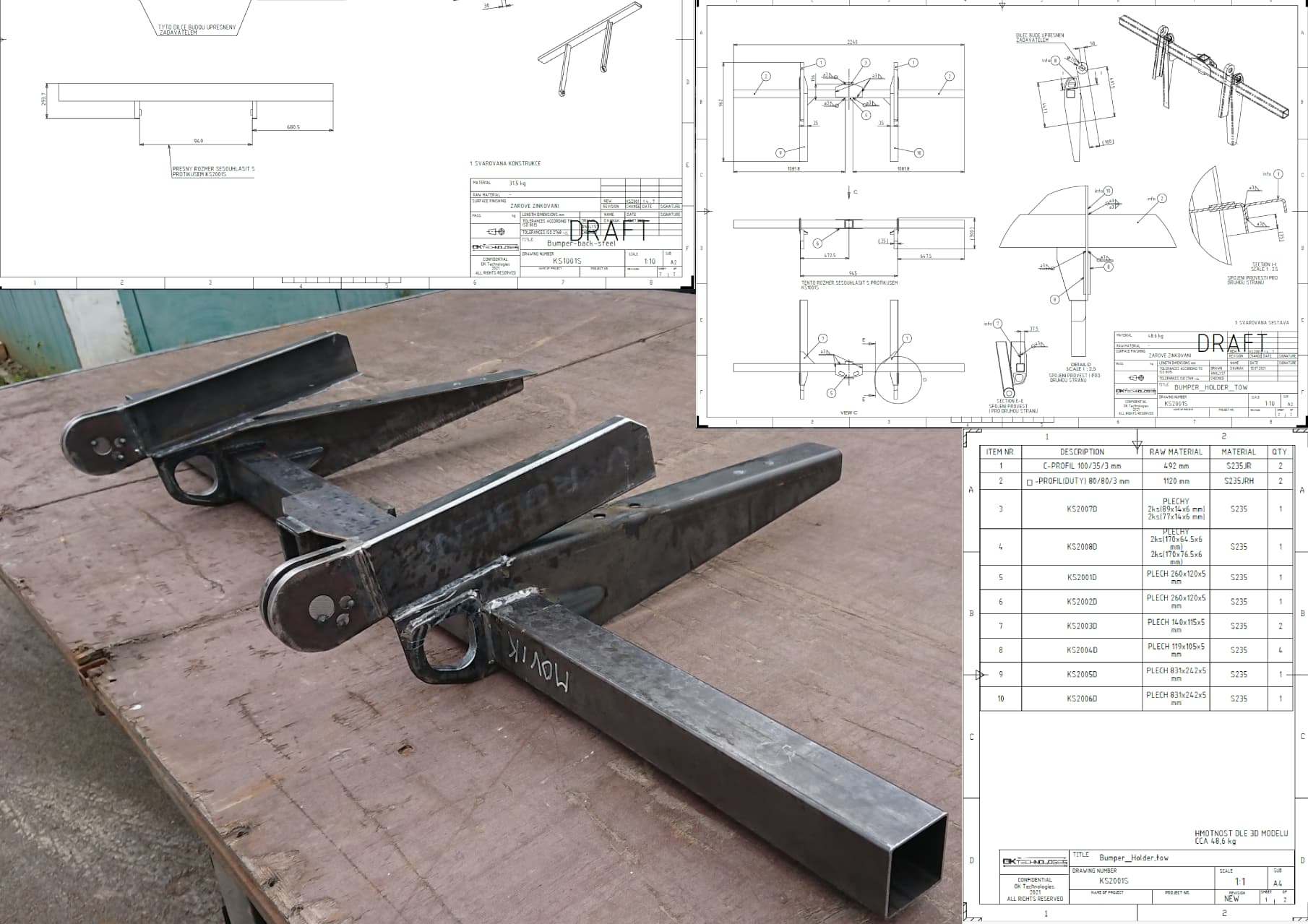

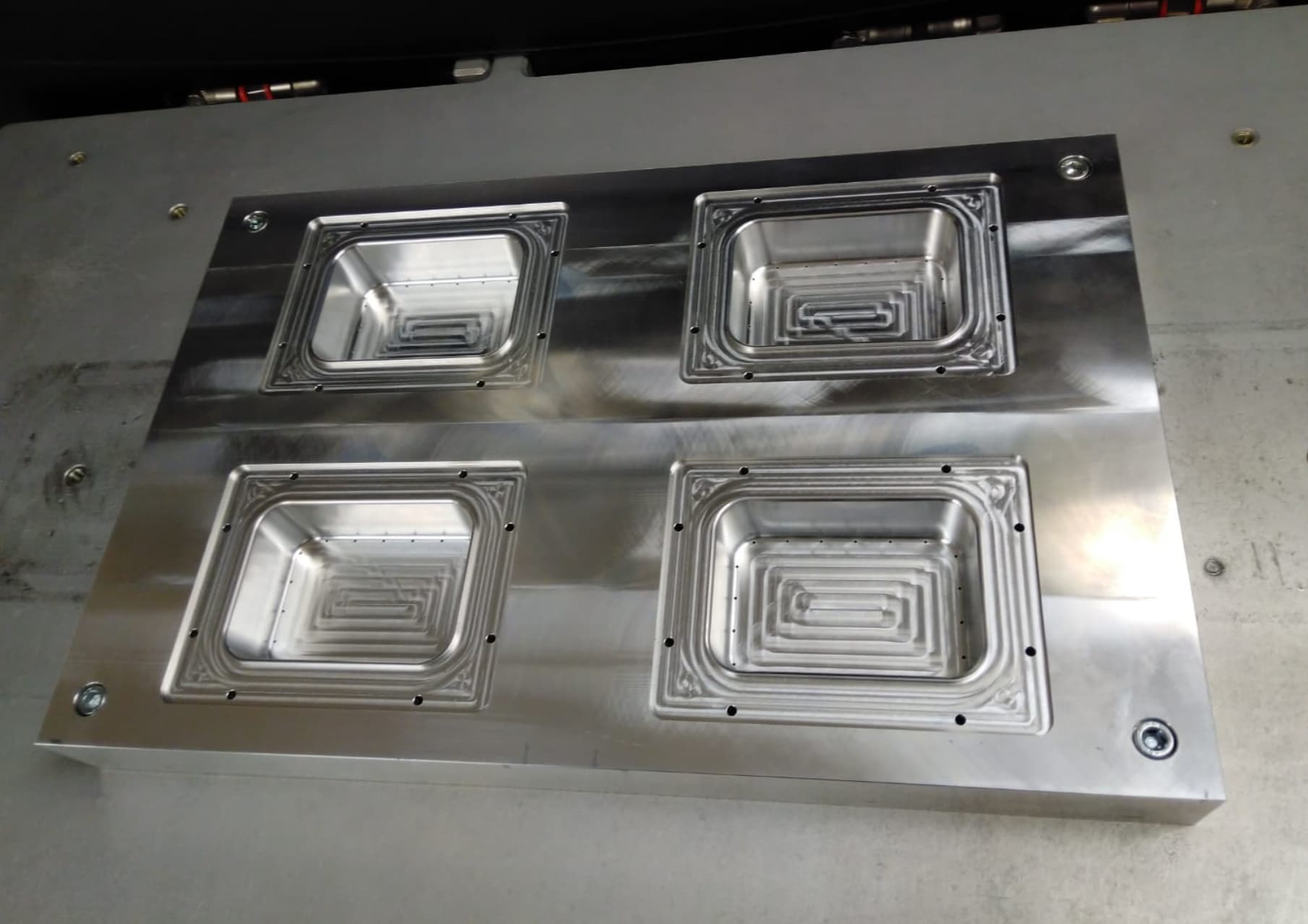

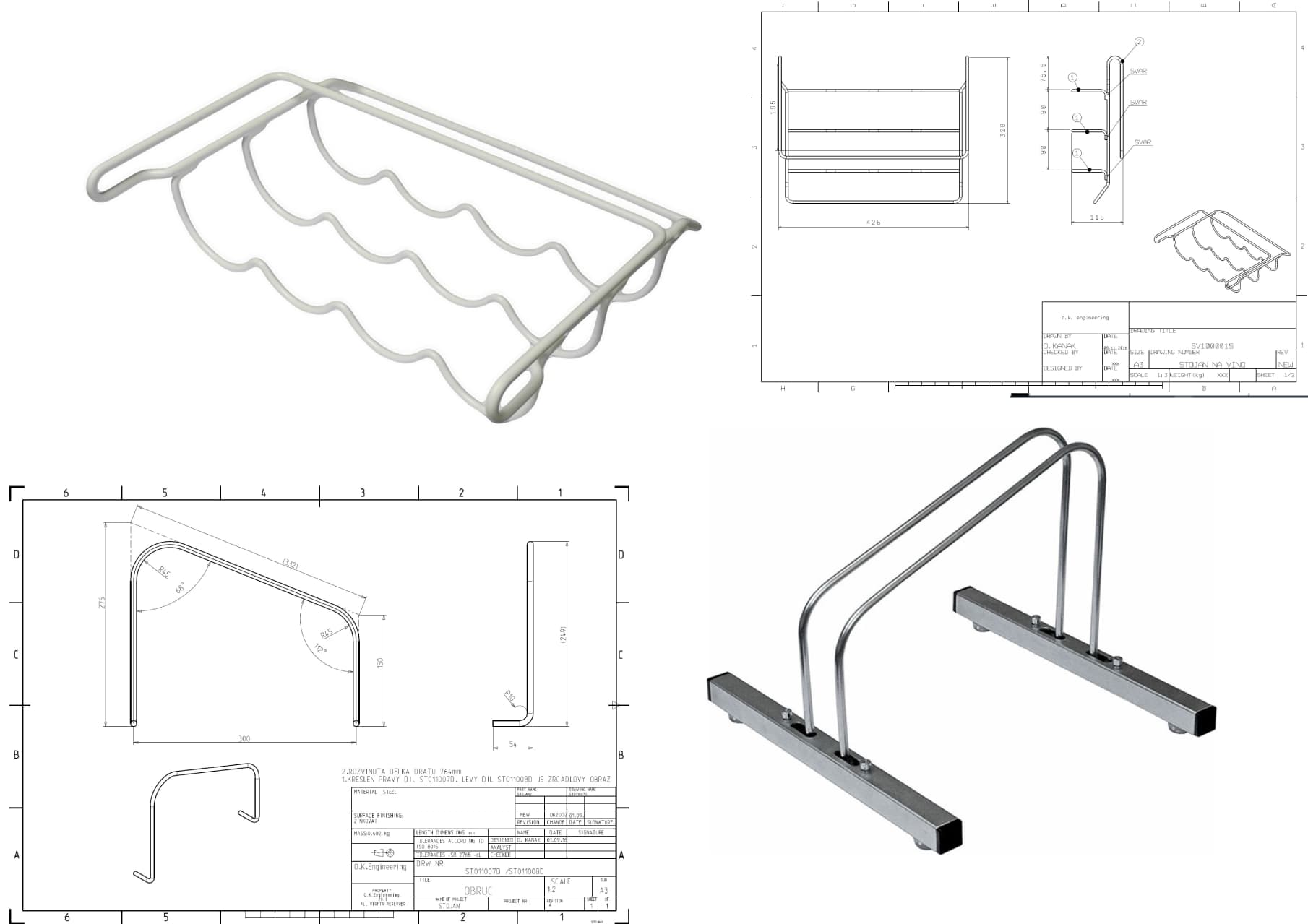

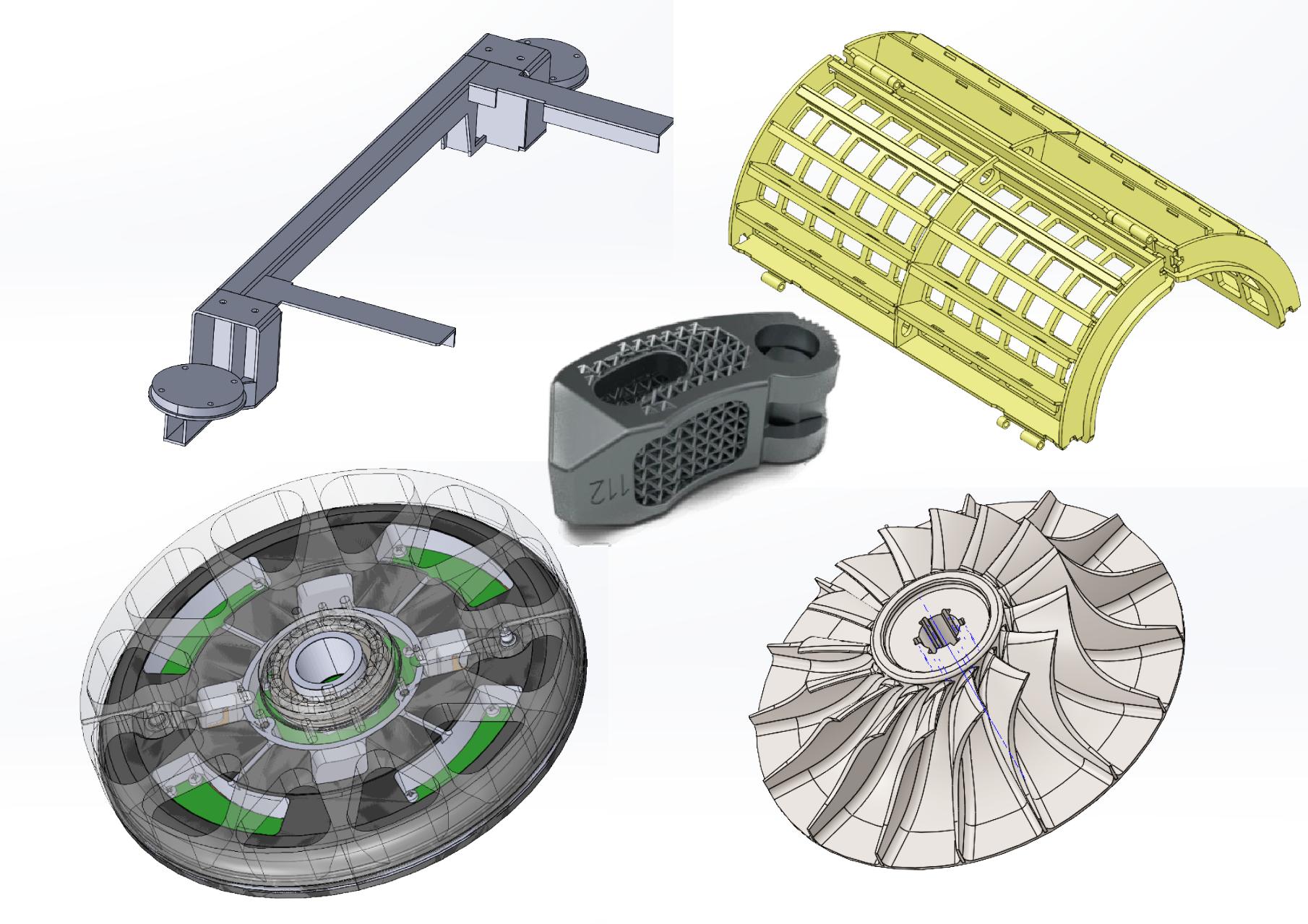

We specialize in the design and development of components for the aerospace and aviation industries. We also collaborate on projects intended for general mechanical engineering, from steel structures and sheet metal parts to molds. We execute projects directly according to customer specifications—from initial design to final processing. We offer both 3D models and complete drawing documentation ready for production, including detailed parts lists and assembly breakdowns. If you need to convert existing documentation into electronic format, we are here for you.

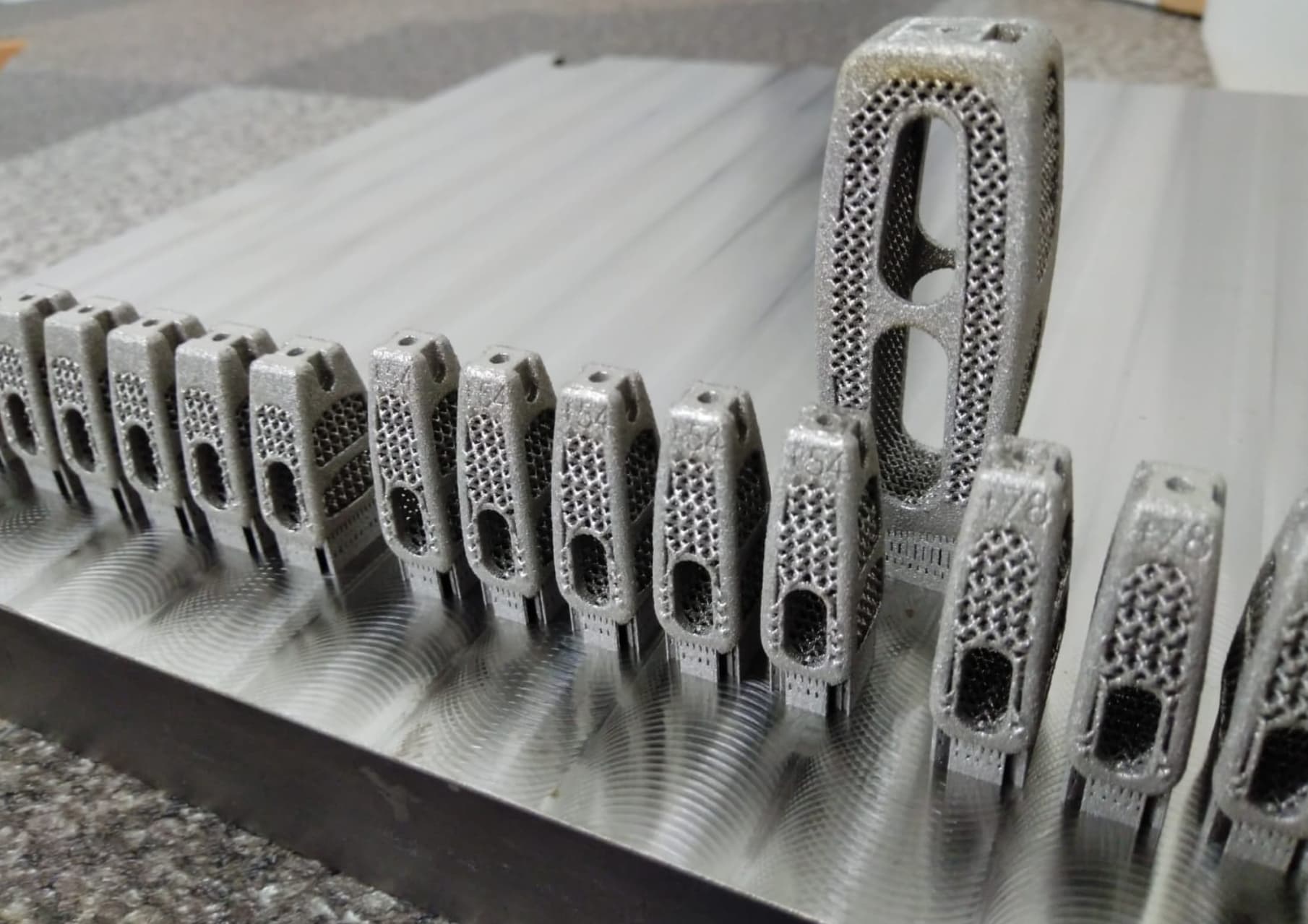

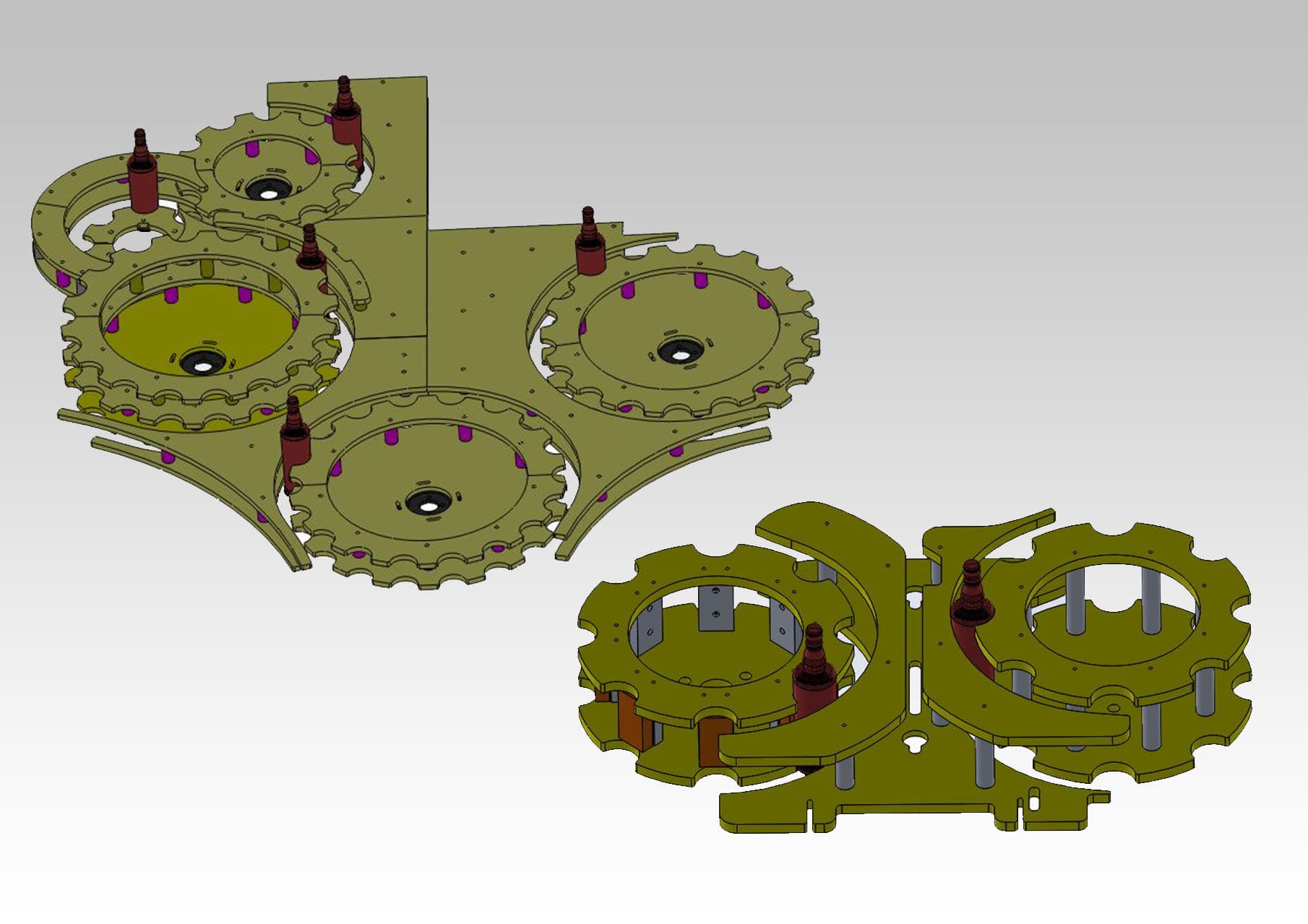

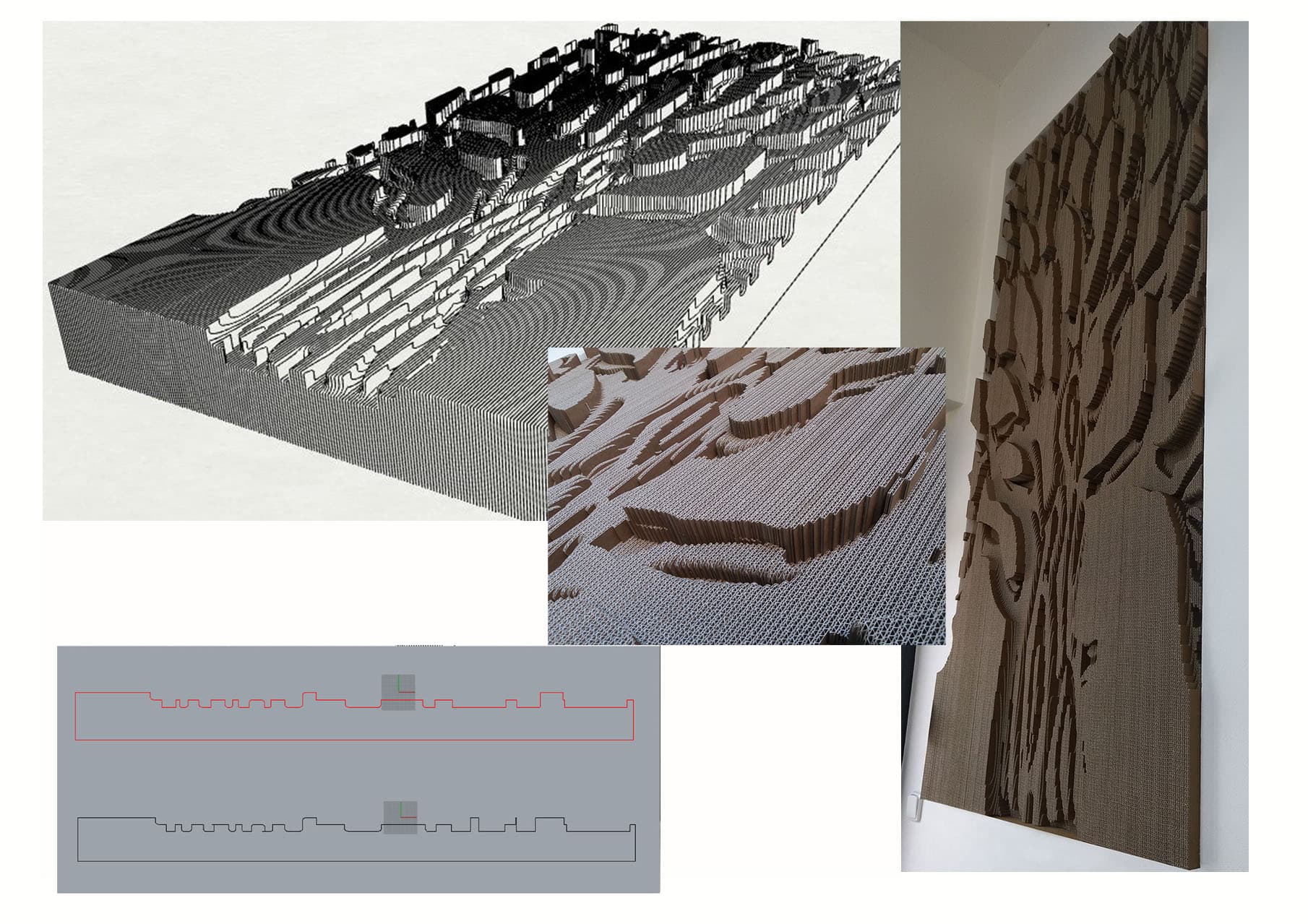

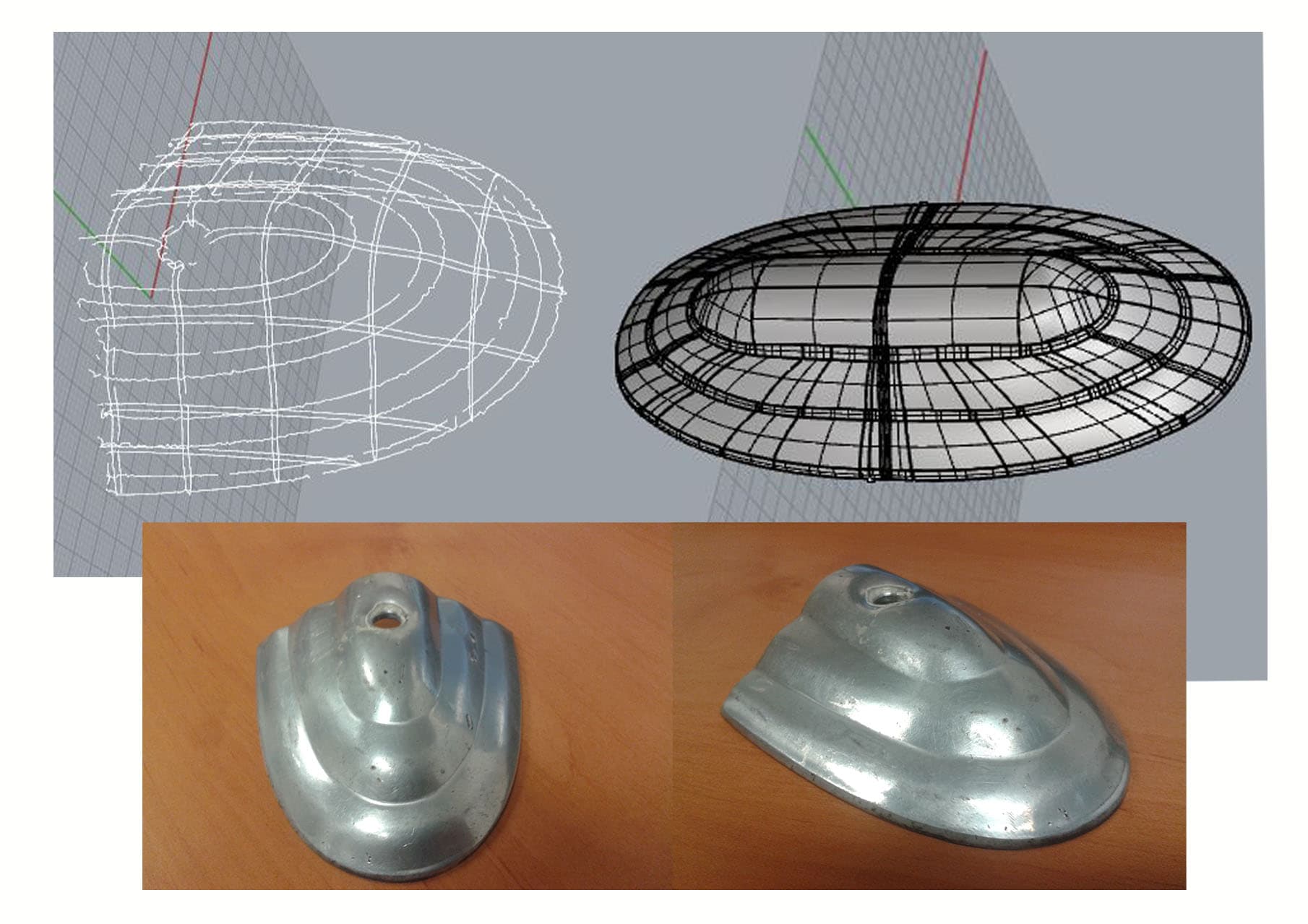

We utilize cutting-edge 3D CAD modeling technologies that ensure efficient product development with minimized costs. Our rapid prototyping methods bring your designs to life and enable quick prototyping or reconstruction of data into 3D models.

We focus on developing individual components, conducting collision simulations in assemblies, and designing mechanisms for machines and production lines. We offer drawing documentation in formats such as PDF and DXF, and 3D models in formats like STEP, IGES, and STL.

3D CAD Models and Integrated Manufacturing

Thanks to 3D modeling, you achieve rapid design and functional testing of components within assemblies. This technique offers significant time savings compared to traditional 2D design and allows for direct integration with manufacturing processes. The 3D data can be immediately used for programming CNC machines.

We use a wide range of software for creating CAD models, including Rhinoceros and SolidWorks, which allows us to meet the requirements of various customers.

If you're looking for a complete solution including production, we can arrange for the external manufacturing of prototypes and small series for you. We offer conventional machining, milling up to 5 axes, turning, wire cutting, welding, bending, as well as precision casting using the lost-wax method.