3D Printing

3D printing is becoming an invaluable tool for professionals in industrial design and architecture, offering revolutionary ways to think about construction and design realization. As an additive process, 3D printing allows for the creation of physical models by layering materials, providing unprecedented flexibility and innovation in design.

What is 3D Printing?

3D printing, also known as additive manufacturing, is a process where final parts are produced by gradually adding material layer by layer. The most common materials include plastic, photopolymer, and others, allowing for a wide range of applications.

Key Methods of 3D Printing

The most well-known methods of 3D printing include:

- FDM (Fused Deposition Modeling): This technique uses thermoplastics to create solid, durable models and is widely used for prototyping and end products.

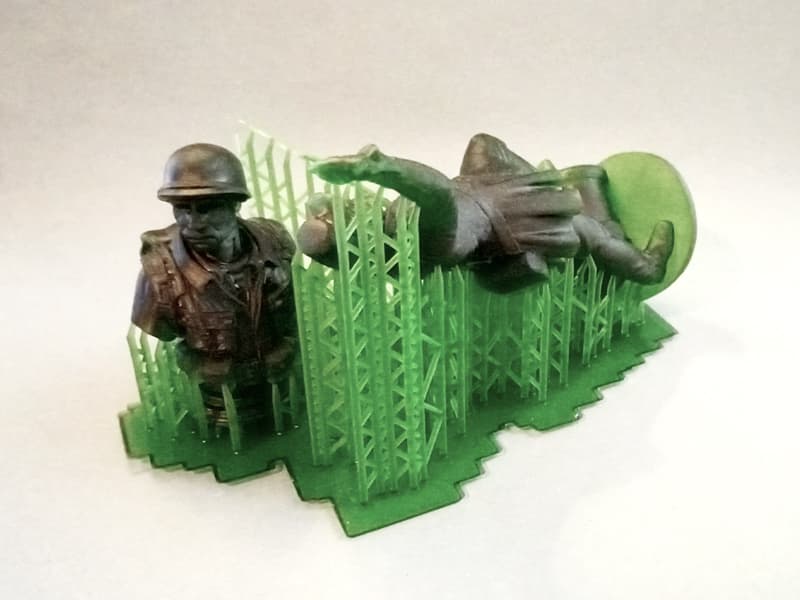

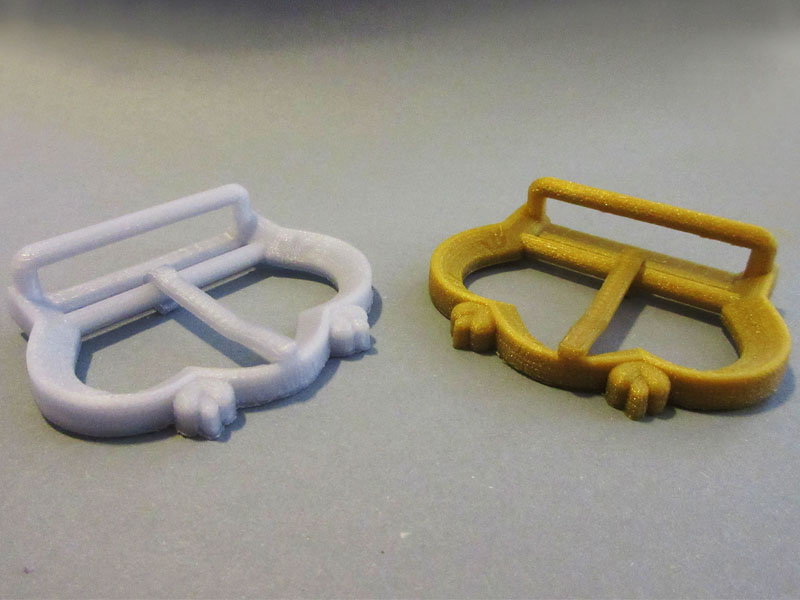

- SLA/DLP (Stereolithography Apparatus/Digital Light Processing): SLA (Stereolithography) and DLP (Digital Light Processing) use UV light to cure photopolymeric resins, enabling the extremely precise production of detailed models.

- SLS (Selective Laser Sintering): SLS (Selective Laser Sintering) uses a laser to sinter powdered materials, creating solid objects without the need for support structures.

How to Prepare Files for 3D Printing

The 3D printing process starts with a digital model. The most common file formats for 3D printing include STL and OBJ, which must be properly modified before printing to match the printer's specifications.

Use of 3D Printing in Industrial Design and Architecture

Thanks to its ability to quickly produce prototypes and complex structures, 3D printing allows designers and architects to experiment with new concepts and test them before final production, reducing development cycles and costs.

3D Printing and Materials for FDM and SLA/DLP Technologies

PLA (polylactic acid )

The most widely used material for 3D printing is PLA (Polylactic Acid). A major advantage is its ease of printing. PLA is a biodegradable polyester product made from plant materials, produced from corn or potato starch or sugarcane. It is extensively used due to its good mechanical properties. When used outdoors, it must be protected from UV radiation as the material becomes brittle. Its temperature resistance is approximately up to 50°C (122°F). PLA is soluble in sodium hydroxide.

ABS (Akrylonitrilbutadienstyren)

It is a thermoplastic industrial copolymer that is resistant to mechanical damage. Particularly suitable for functional components, it exhibits good material properties. It is rigid, tough, and resistant to both low and high temperatures, minimally absorbent, and non-toxic. It is resistant to acids, hydroxides, hydrocarbons, oils, and fats. ABS is very easy to work with. It is suitable for further surface finishing, easily grindable, and can also be glued.

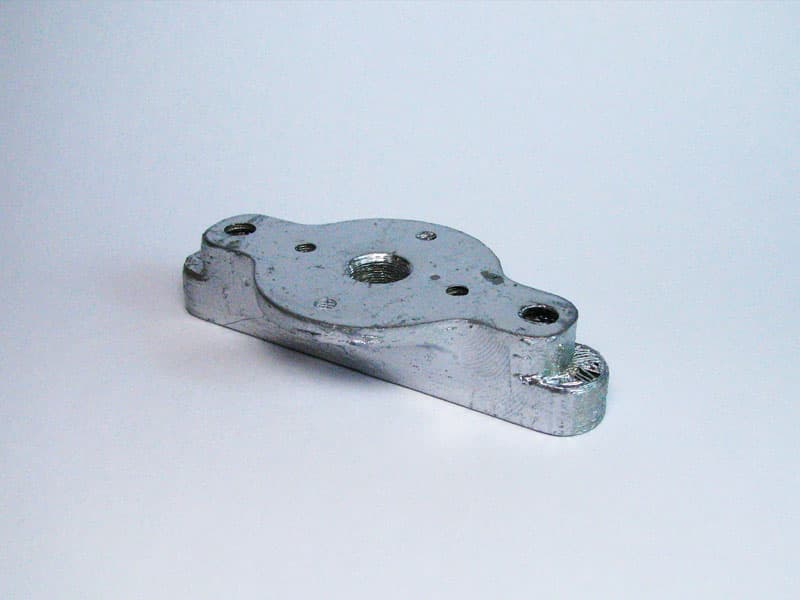

Mold Lay

It is a plastic filament with wax-like properties. Its use is primarily in foundry applications for the creation of wax models and subsequently castings. It can be glued with superglue and is not soluble in acetone. It features almost zero deformation. The properties for printing are almost identical to PLA.

PET

For 3D printing, its derivative with glycol, PET-G, is used, resulting in a filament that is less brittle and highly impact-resistant. PETG filament combines the properties of ABS materials (stronger, more temperature resistant, more durable) and PLA (easy to print). The risk of shrinkage is not as significant. It is fully recyclable.

PA (NYLON)

It is a very compact polyamide. It is a strong and durable material with high flexibility in thin layers, but with very high adhesion (stickiness) between layers. Its low coefficient of friction and high melting temperature make it an excellent choice for 3D printing functional and technical parts. Nylon is very sensitive to moisture. The filament must be absolutely dry. If not, bubbles will form in the material. Dry nylon filament prints smooth objects with a glossy surface. It is not naturally biodegradable.

TP (FLEX)

These are thermoplastic elastomers, made from a mixture of hard plastic polymers and soft rubber materials. They contain additives, which may include oil, fillers, and others. These materials particularly resemble rubber in terms of properties. They are used for 3D prints where flexibility is important. For 3D printing itself, they are among the more complex materials to work with.

UV resin

These are special resins that are sensitive to the UV spectrum of radiation. The print needs to be cured in direct sunlight or using a special UV lamp. The print is hard and brittle. Used for printing by the SLA/DLP method.